Tatami Mats

Japanese tatami are distinguished by:

- Perfect workmanship

- Omote (woven grass surface): Long-fibered, and therefore highly durable quality. Four different finishes are available. The material comes from organic cultivation in Kumamoto / Kyushu.

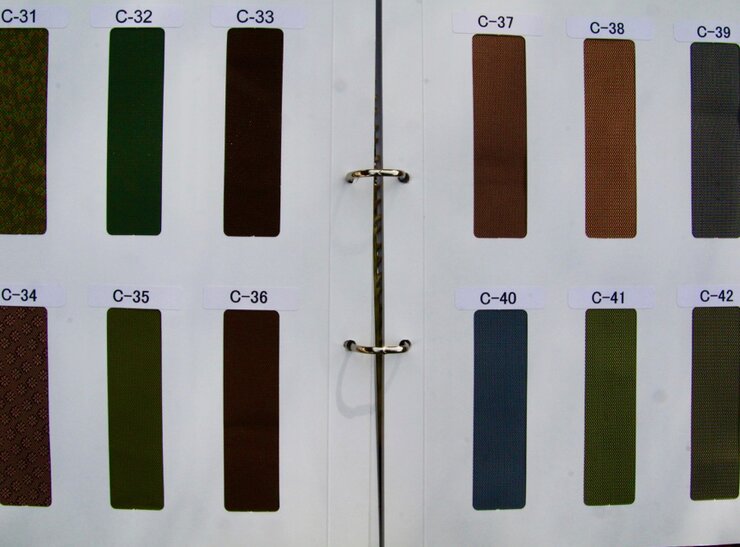

The initially greenish Omote quickly develops the typical straw-colored tatami hue when exposed to light. This even discoloration—achieved through careful selection of the grass—is another mark of quality. - Alternative: Instead of Igusa grass, there is also a woven variant made from Japanese paper (appearance similar to a loom weave, but without wire). Very robust, available in various colors, and interesting for modern interiors.

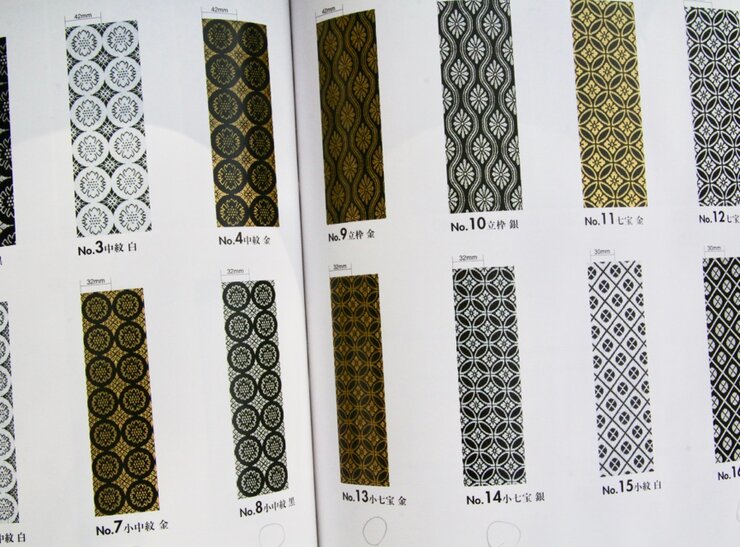

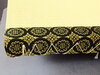

- Beri (edge band): You can choose between 84 “house” variants and 66 brocades that are traditionally used in temples.

- Core: Today, about 90 % of all mats in Japan are made with wood‐fiber boards. Thickness ranges from 15 to 60 mm (for underfloor heating, a maximum of 30 mm). The stepping feel is similar to that of a new straw core, but the weight of a mat is significantly lower.

- Teahouse tatami: For tea rooms, a specially crafted Omote in the Kyoto size is offered.

For this, grass sorting, warping, and the attachment of the Beri must meet additional, more stringent requirements.

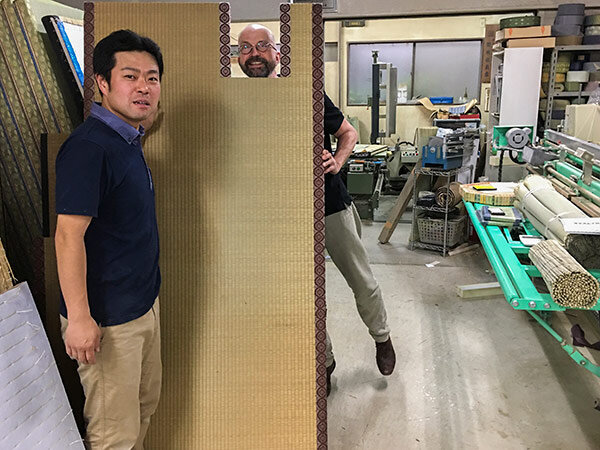

Our manufacturer in Kyoto

We have been working for a long time with two manufacturers, one in Kyoto and the other in Tokyo. They are small artisanal workshops that have specialized in producing tatami for many generations.

Omote

For the selection of the surface (Omote), many variants are available: either Igusa grass in various qualities or, increasingly popular in recent years, Omote made of Japanese paper.

Beri

When selecting the Beri (tatami borders), a wide variety of options is available. Here is a small excerpt from the catalogs. For a deposit, we will gladly send you the originals.

Tatami filling

For the filling of the tatami, two variants are available: either traditional rice straw or wood‐fiber boards, offered in thicknesses from 15 to 60 mm in approximately 5 mm increments.

For underfloor heating, manufacturers recommend tatami with a maximum thickness of 28 mm.

There are also versions with polystyrene filling, which are exceptionally lightweight.

Cutouts and Special Requests

Since all mats are custom-made, it is also easy to accommodate special requests, such as cutouts for a winter hearth in the tea room or for columns—whether round or square. Everything will fit perfectly; the tolerance with which the mats are manufactured is ±1 mm!

Price, Payment, and Shipping

These tatami are crafted in small artisanal workshops in Japan, and their quality meets the highest standards. That comes at a price, but it is rewarded by longevity and precision.

Costs depend on various factors—such as size, core, Omote, and also Beri. Therefore, it is difficult to state a standard price, but on average it is approximately €500 per piece, including elaborate packaging, German value-added tax, and shipping from Japan to Seeon.

I try to reduce shipping costs by placing group orders.

The exact situation needs to be discussed on a case-by-case basis.

As a rule, shipping is done by sea freight. The tatami will then be delivered to you by a freight forwarder, although pickup in Seeon is also possible. For individual tatami with a wood-fiber core and low weight, air freight is an option.

Production can usually be completed within three weeks. Sea transport takes about 40 days; afterward, customs clearance and delivery from Hamburg to Seeon follow.

We will also be happy to provide you with a layout proposal that will be adapted to the conditions of your rooms.

Once the type and size of your tatami have been determined, I will prepare an offer for you. If you agree, I ask for a deposit of half the quoted price. After receipt of payment, your tatami will be ordered in Japan.

Production of your tatami typically requires 14–20 days.